AEROLANTECH

Aerobic Landfill Technologies Inc.

Technology

Aerobic Process

Well Drilling

Mining & Separation

Conventional Landfills

Conventional landfills are anaerobic (oxygen-deprived) and pose environmental risks to air, water and land through methane and carbon dioxide gas emissions, intense odour production and leachate generation. Leachate is a nasty-smelling landfill liquid containing high concentrations of organics, nutrients and metals that can contaminate the surrounding soil and groundwater. Conventional landfills are merely long-term garbage tombs that degrade waste extremely slowly and cause environmental issues lasting in excesss of 100 years.

The Sustainable Landfill

ALT's sustainable landfill solution consists of three processes:

- Aerobic Bioreactor

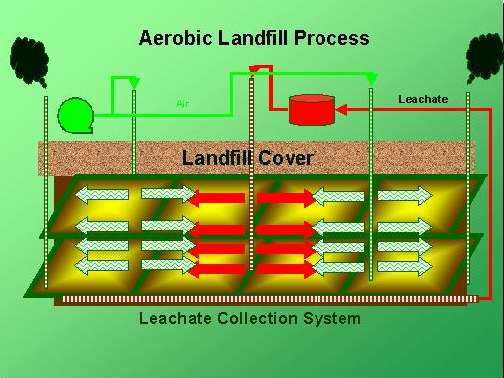

ALT's aerobic process immediately and dramatically changes the condition of a landfill. Wells are drilled on the site for air and moisture injection and landfill gas extraction. Anaerobic bacteria are quickly rendered inactive and are replaced by aerobic bacteria, which rapidly decompose the organics. Landfill leachate and/or municipal sludge can be used as a moisture source (where approved), resolving yet another environmental issue!

The environmental benefits are immediate. Methane production ceases within 2 to 3 weeks and odours are virtually eliminated. Organics decompose in 3 to 5 years. Leachate quality is vastly improved and the volume is significantly reduced. As the process continues, the site will compact and visibly "slump", recapturing up to 30% of the original airspace.

The aerobic process can be applied to both operating and closed landfills.

- Mining & Material Recovery

When the aerobic cycle has completed, the site can be excavated using open pit mining techniques. Composted material is removed and recyclable materials (metals etc.) can be recovered. Any hazardous materials such as batteries, propane cylinders and chemical drums can then be disposed of appropriately.

- Product Manufacturing

With the assistance of the National Research Council of Canada, ALT has developed a process to manufacture durable products from the remaining materials (co-mingled plastics, glass, rubber, carpet, etc.). Products such as utility poles, railway ties, marine wharving and landscaping materials can be manufactured. These products are exceptionally cost-effective, impervious to erosion, non-toxic, and exhibit high tensile and flexural characteristics. Alternatively, high BTU waste such as co-mingled plastics and carpet can be processed into biodeisel or pelletized for use as a fuel source. Either of these companion technologies will provide dividends to the landfill owner.

By using ALT's sustainable landfill technologies, more than 90% of

stored waste can be reintroduced into the circular economy through

recycling or value added product manufacturing.